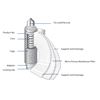

Material of filter element components:

Filter material : Hydrophilic polyvinylidene difluoride (PVDF)

Supports/Diversion : PP

Core/Cover/End cover/End caps : PP

Sealed leads/Fins : PP,Built in stainless steel

O-Ring : 222,226 silicon rubber, washer with double split etc.

Sealing technology : Thermal bonding without adhesives

Characteristics and features

- Excellent high-temp resistance and extensive chemical compatibility.

- Low protein adsorption performance, suitable for filtration of culture solution, biological reagent and aseptic vaccine.

- The samples of filter cartridges successfully passed the bacterial retention testing required by regulations, LRV>7. Integrity can be maintained after repeated disinfection.

- Each filter cartridge should pass the integrity test before leaving the factory. The limitations of integrity testing were correlated with the results of bacterial retention testing.

- All the compositions meet the requirements of the biological testing characteristics of USP Class 6 plastic products at 121°C and the food contact materials listed in the relevant regulations of Chapter 21 of the Federal Regulations of the United States (CFR).

- It is manufactured under ISO 9001 and ISO 14001 systems and Class 100 clean environment.

- Production and usage are traceable.

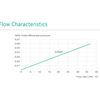

Technical specifications and operating parameters

Size | Diameter: 2.75"(69 mm) Length: 2.5"/5"/10"/20"/30"/ 40" etc. |

Removal Ratings (µm) | 0.22, 0.45 |

Filtration area | Single 10" filter element is about 0.65m² |

| Maximum Differential Pressure | 0.4MPa/21℃, 0.24MPa/80℃

|

Maximum Operating Temperature | 80℃ |

Steam Sterilization | 121℃/30min. |

Typical Application

- Filtration of blood products

- Filtration of biological reagent

- Filtration of culture medium

- Filtration of vaccines

- Sterilization filtration of antibiotic solution

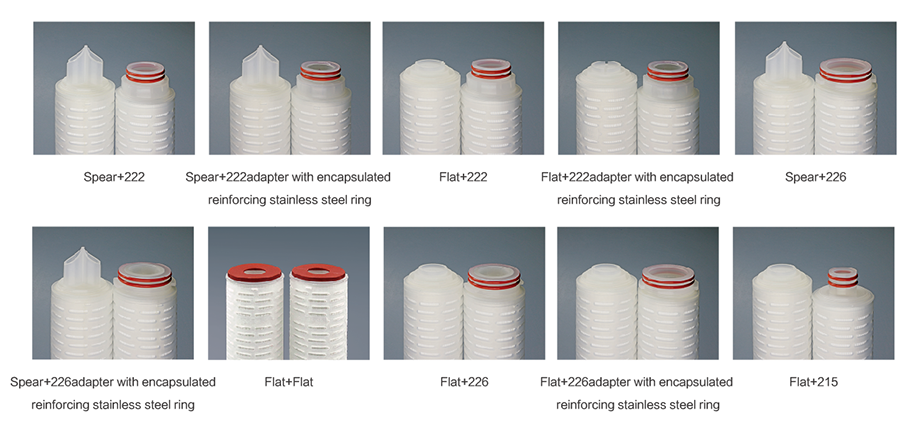

Adapter Style

Ordering information

1 | 2 |

| 3 | 4 | 5 | 6 | 7 |

PVDF | 0.22 | --- | 10 | A | S | P | --X |

1 | Membrane | Hydrophilic polyvinylidene difluoride (PVDF) |

2 | Pore size | 0.22 / 0.45μm |

3 | Length | 2.5" / 5” / 10” / 20” / 30” / 40” |

4 | Connector/End Cover A/AA/B/BB/C/CC/D/E/EE/F | Spear+222 Spear+222adapter with encapsulated reinforcing stainless steel ring Flat+222 Flat+222adapter with encapsulated reinforcing stainless steel ring Spear+226 Spear+226adapter with encapsulated reinforcing stainless steel ring Flat+Flat Flat+226 Flat+226adapter with encapsulated reinforcing stainless steel ring Flat+215 Spear+3 Flange Bayonet adapter |

5 | Gasket Material S, E, F, FF | S: Silicon rubber E: EPDM rubber F: Fluorine rubber FF: Encapsulated fluoroelastomer |

6 | Application | Pharmaceutical grade for bio-pharmaceutical&food and beverage industry |

7 | Special Specification Remarks | Standard Specification Default |