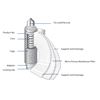

Material of filter element components:

Filter material : Nylon 66 Membrane (NL66)

Supports/Diversion : PP

Core/Cover/End cover/End caps : PP

Sealed leads/Fins : PP,Built in stainless steel

O-Ring : 222,226 silicon rubber, washer with double split, etc.

Sealing technology : Thermal bonding without adhesives

Characteristics and Features

- Excellent high-temp resistance and alkali resistance.

- Strong oil and solvent resistance.

- The samples of filter cartridges successfully passed the bacterial retention testing required by regulations, LRV>7.

- Each filter cartridge should pass the integrity test before leaving the factory.

- All the compositions meet the requirements of the biological testing characteristics of USP Class 6 plastic products at 121°C.

- The food contact materials listed in the relevant regulations of Chapter 21 of the Federal Regulations of the United States (CFR).

- It is manufactured under ISO 9001 and ISO 14001 systems and Class 100 clean environment.

- Production and usage are traceable.

Technical specifications and operating parameters

Size | Diameter: 2.75"(69 mm) Length: 2.5"/ 5"/10"/20"/30"/ 40" etc. |

| Removal Ratings (µm) | 0.22, 0.45 |

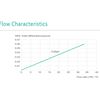

Filtration Area | Single 10" filter element is about 0.65m² |

Maximum Differential Pressure | 0.4 MPa/21℃, 0.24 MPa/80℃ |

| Maximum Operating Temperature | 80 ℃ |

Steam Sterilization | 121℃/30 min. |

Typical application

Filtration of photoresist developer

Terminal filtration of deionized water, pure water, ultrapure water or process water

Filtration of beer, wine and dairy products

Filtration of ink, resin, solvent, pigment, etc.

Terminal sterilization filtration of purified water and water for injection

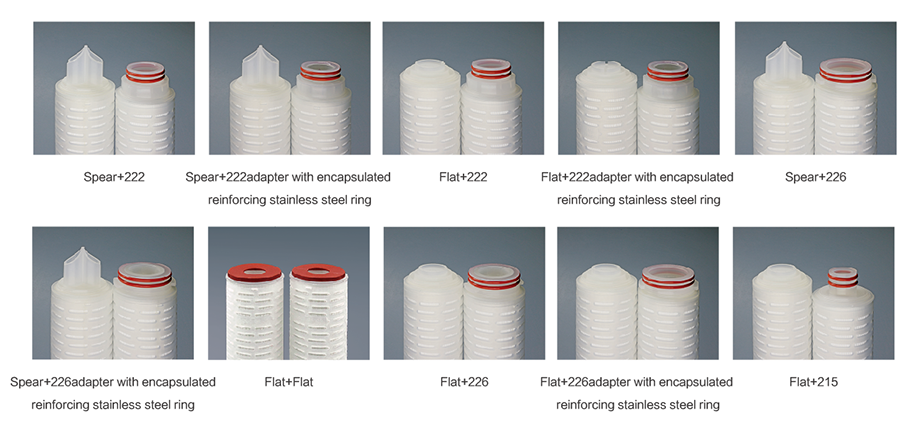

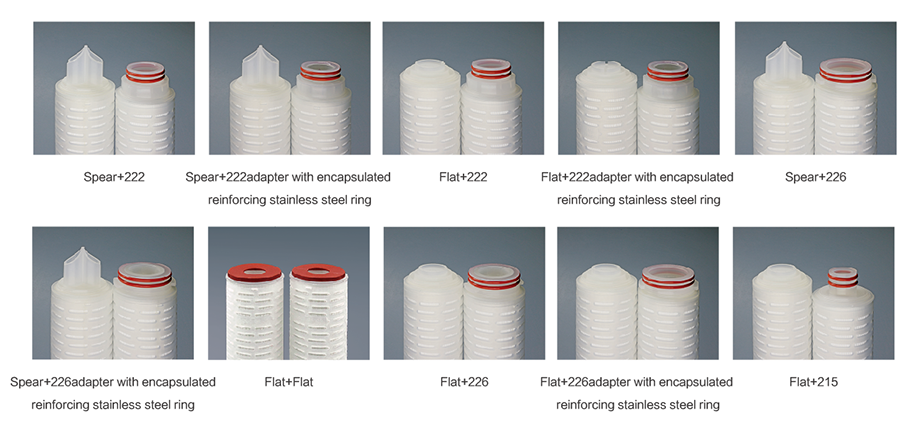

Adapter Style

Ordering information

1 | 2 |

| 3 | 4 | 5 | 6 | 7 |

ZNL | 0.22 | --- | 10 | A | S | P | --X |

1 | Membrane | Nylon 66 Membrane (NL66) |

2 | Pore size | 0.22 / 0.45μm |

3 | Length | 2.5"/ 5” / 10” / 20” / 30” / 40” |

4 | Connector/End Cover A/AA/B/BB/C/CC/D/E/EE/F | Spear+222 Spear+222adapter with encapsulated reinforcing stainless steel ring Flat+222 Flat+222adapter with encapsulated reinforcing stainless steel ring Spear+226 Spear+226adapter with encapsulated reinforcing stainless steel ring Flat+Flat Flat+226 Flat+226adapter with encapsulated reinforcing stainless steel ring Flat+215 Spear+3 Flange Bayonet adapter |

5 | Gasket Material S, E, F, FF | S: Silicon rubber E: EPDM rubber F: Fluorine rubber FF: Encapsulated fluoroelastomer |

6 | Application | Pharmaceutical grade for bio-pharmaceutical&food and beverage industry |

7 | Special Specification Remarks | Standard Specification Default |