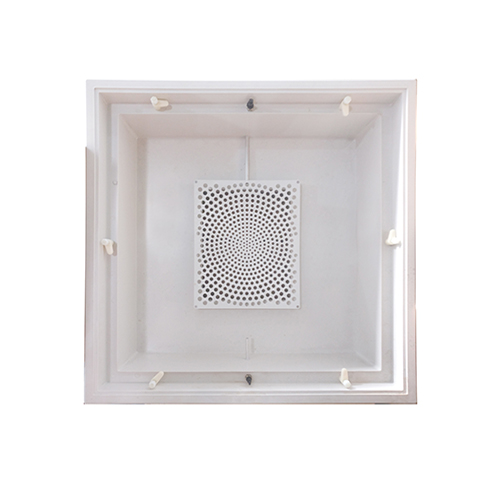

Operation principle: It aims to provide the air with desirable static pressure before passing through HEPA filter, to enable uniform air-out. The HEPA box requiring filed leak detection is provided with PAO dusty entry and upstream concentration detection mouth, and differential pressure detection mouth and lower damper based on customers’ requirements.

Type: There are a number of sealing modes, such as dry-type sealing, wet-type sealing, dry & wet double sealing negative pressure type, wet-type double sealing negative pressure type available. The case material may be plastic-spry steel plate, SUS304 stainless steel plate, aluminum alloy section, ABS plastic etc.

Application: Food, pharmaceuticals, bioengineering, microelectronics, etc.

Advantage for ABS Plastic HEPA Box:

1. one time injection,no leakage risk,smooth inner surface,dust-free,easy to clean.

2. Acid-,alkali-and salt-resistant,formaldehyde-resistant,VHP and O3 Sterilize.

3. Flame - retardant: UL94-V0.

4. Flame - retardant, corrosion resistance, high intensity and other features, SGS&BV certificated.

Advantage for Plastic-spry Steel HEPA Box:

1. Full welding with mechanical arm, high efficiency.

2. No leakage risk.

3. The box is not easy to deform.

4. The adhesive force of the plastic spraying layer is stronger after the phosphating treatment.

standard size and parameter

Model | Size of HEPA

(mm) | Size of Box

(mm) | Flange Size of Duct

(mm) | Rated Airflow

(m3/h) | Matching hole size

(mm) |

LHB5S-46.46 | 410×410×93 | 460×460×225 | 200×200 | 500 | 470×470 |

LHB5S-60.60 | 550×550×93 | 600×600×225 | 320×200 | 1000 | 610×610 |

LHB5S-70.70 | 650×650×93 | 700×700×225 | 320×250 | 1500 | 710×710 |

Note: For ABS box,the hole size should be 5mm larger than that in the list,for plastic-spray box with DOP outside,the hole size should be 5mm smaller than that in the list .We can also produce other sizes according to customer’s requirements.