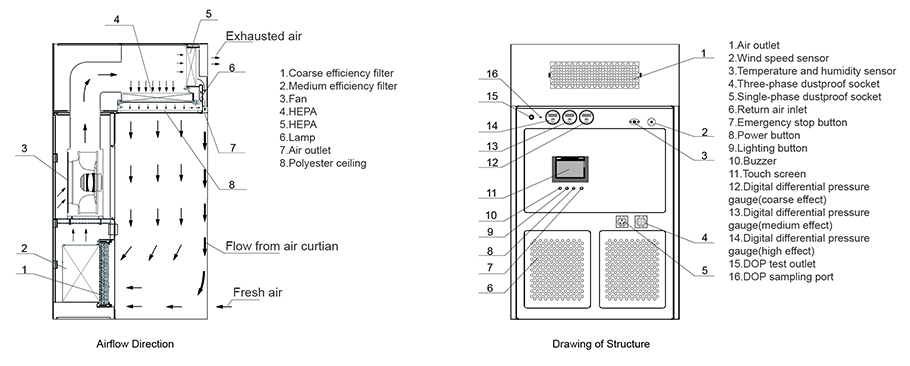

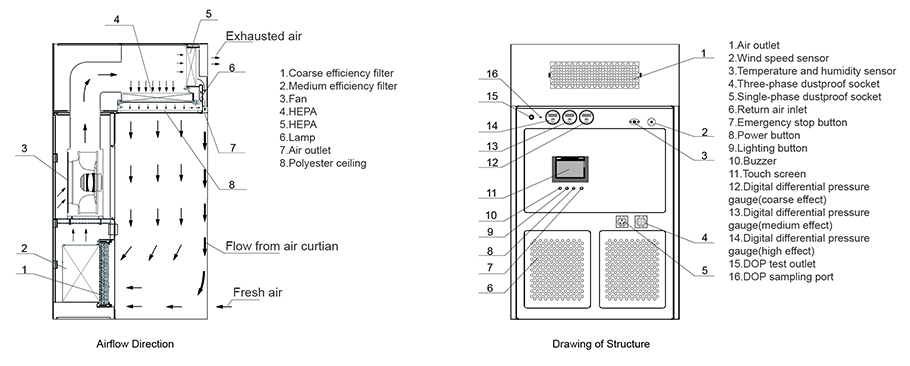

Operational principle: The Dispensing Booth includes primary, middle & HEPA filters and provides vertical unidirectional airflow to the working area which can control the dust flying effective. Most of the clean air will be circuited in the working area and a small quantity of clean air will be exhausted into the background to ensure the negative-pressure in working area and prevent cross contamination in order to protect the cleanliness in the environment and safety of the operators.

Installation method: A modular build format, allows ease of installation and as a result to provide less downtime.

Applications: Sampling room, dispensing room and weighing room in pharmaceutical, micro-organism studies, science laboratory, etc.

Advantages:

1. Integrated circular are designed for the working area,no dead angles,dust-free,easy to clean.

2. Wind curtain isolated,with personnel and materials easily pass in and out,convenient operation.

3. Unique patent design,slight temperature difference between the work area and background area.

4. Excellent unidirectional flow pattern,no dust proliferation,great capturing effect with flow pattern.

Product schematic diagram

Standard size and parameters

Model | Overall size

W×D×H | Working size

W×D×H | Rated air velocity

(m/s) | Working area

clean class | Power

(kw) |

LWR 12-120.60 | 1300×1200×2570 | 1200×600×2000 | 0.45±20% | Same to background | 0.3 |

LWR 16-120.100 | 1600×1800×2570 | 1500×1200×2000 | 0.45 |

LWR 24-120.120 | 2100×2700×2570 | 2000×2000×2000 | 0.6 |

LWR 32-120.100 | 3100×2700×2570 | 3000×2000×2000 | 0.9 |

LWR 48-120.120 | 4100×3200×2570 | 4000×2500×2000 | 1.2 |

Note: specifications listed in below table are only for customer’s reference. It is mostly designed and manufactured according to customer’s URS.