Features

High velocity shower jets in excess of 25m/s ensure efficient scrubbing action to remove particulate matter.

Operating modes can be programmed in the field.

Control panel supervises all functions.

HEPA filter, filtration achieves > 99.99% typical efficiency at 0.3 micron particles.

A disposable pre-filter with 85% arrestance extends the life of the main filter.

An emergency stop button is mounted on sides of the shower.

Auto-Inductive when people come into the booth and the air nozzle begin to work.

Permanently lubricated direct drive centrifugal blowers are used in conjunction with stainless steel air nozzles.

Interlock Door System.

Technical Specification

Power supply | 380V50Hz |

Power | 1.5KW |

Two stage filtration system | G4 coarse filter/H14 Efficiency configuration DOP detection port(High side tank filter) |

Noise | 65-75dB(A) |

Differential pressure gauge | High efficiency display differential pressure gauge(USA DWYER) |

Sensor | Air speed sensor ( E+E) |

Buzzer | Pressure difference, fault alarm |

Button | Power supply (luminous ring visible buttons) with emergency stop |

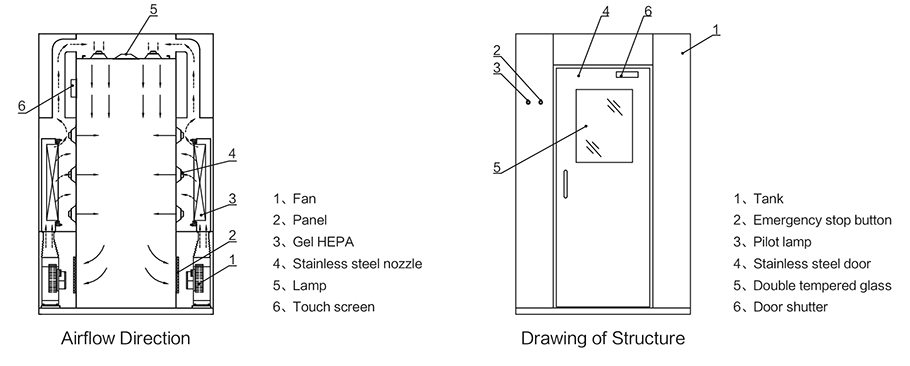

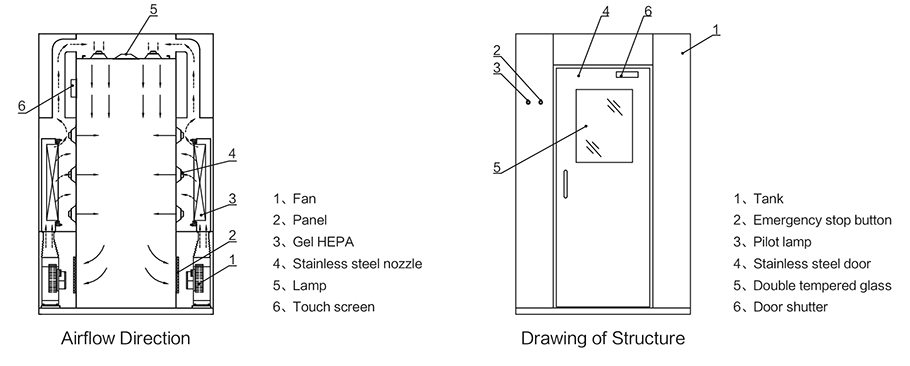

Product schematic diagram

standard size and parameters

Model | Overall size

W×D×H | Work area size

W×D×H | Air

Volume

(m/s) | Number

of

nozzles | HEPA size

L×W×D |

ASR-080090 | 1200×1000×2150 | 800×900×1950 | 25 | 6 | 650×650×93×1 |

ASR-080090 | 1400×1000×2150 | 800×900×1950 | 12 | 650×650×93×2 |

ASR-080140 | 1400×1500×2150 | 800×1400×1950 | 18 | 955×650×93×2 |

ASR-080190 | 1400×2000×2150 | 800×1900×1950 | 24 | 650×650×93×4 |

ASR-080290 | 1400×3000×2150 | 800×2900×1950 | 36 | 955×650×93×4 |

Note: Air shower room and air shower channel not listed in the table can be made according to the customers' requirements