Features:

Product transfers in aseptic conditions.

Wireless solution (battery equipped).

Unidirectional flow; vertical or horizontal.

Designed for the particular transfer process.

Easy to clean design with single welded construction.

HEPA knife edge gel seal design.

Technical specification:

Housing: Body structure fully made in stainless steel SS304 press-bent metal sheets.

Filter: Filtration stages consisting of G4 pre-filter with typical arrestance of A≥90% according to EN 779 fitted on stainless steel cell with quick release system (no screws needed to remove the panel) and low pressure drop H14 HEPA filter according to EN 1822.

Ventilation provided by energy efficiency low power consumption motor blower.

Power supply: Dry battery UPS recovery pack with theoretical battery duration of 2-4 hours starting from full charge status. UPS unit is provided with charge indicator

Dop Port: DOP test port at upstream of HEPA filter to personnel for carrying out the HEPA filter integrity test.

Mobility: Pivoting (360°) castors with brakes.

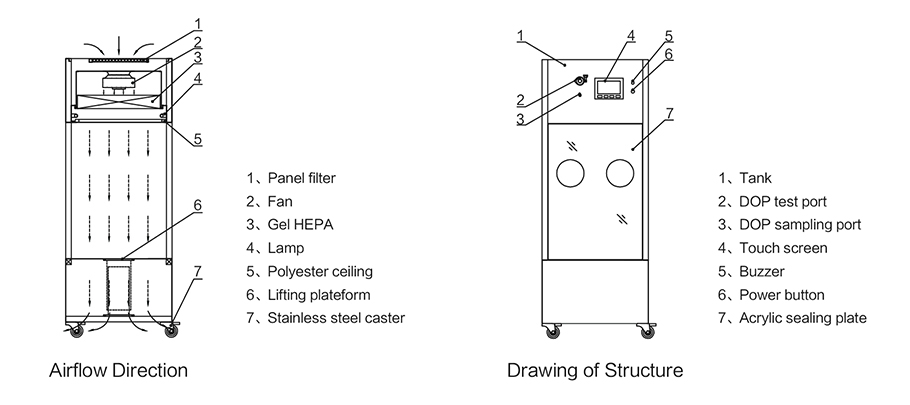

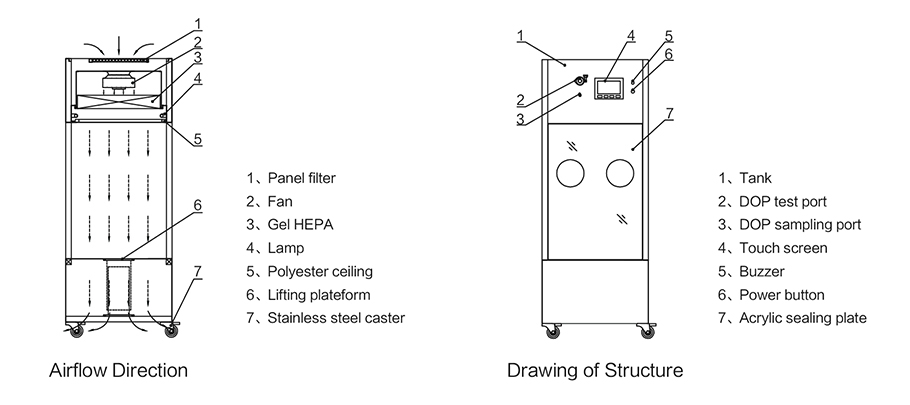

Product schematic diagram

standard size and parameters

Model | Overall size

L×W×H | Work size

L×W×H | pstream Rated

air velocity

(m/s) | Working area

clean class | Power

(kw) |

LUFT8-072058 | 800×600×1800 | 720×580×750 | 0.45±20% | Class A | 0.4 |

LUFT10-092058 | 1000×600×1800 | 920×580×750 | 0.4 |

LUFT14-112068 | 1200×700×1800 | 1120×680×750 | 0.5 |

Note: specifications listed in below table are only for customers' reference. It is mostly designed and manufactured according to customers' URS.